Purdue innovation takes the lead at Olympic swimming pool project in Lucas Oil Stadium

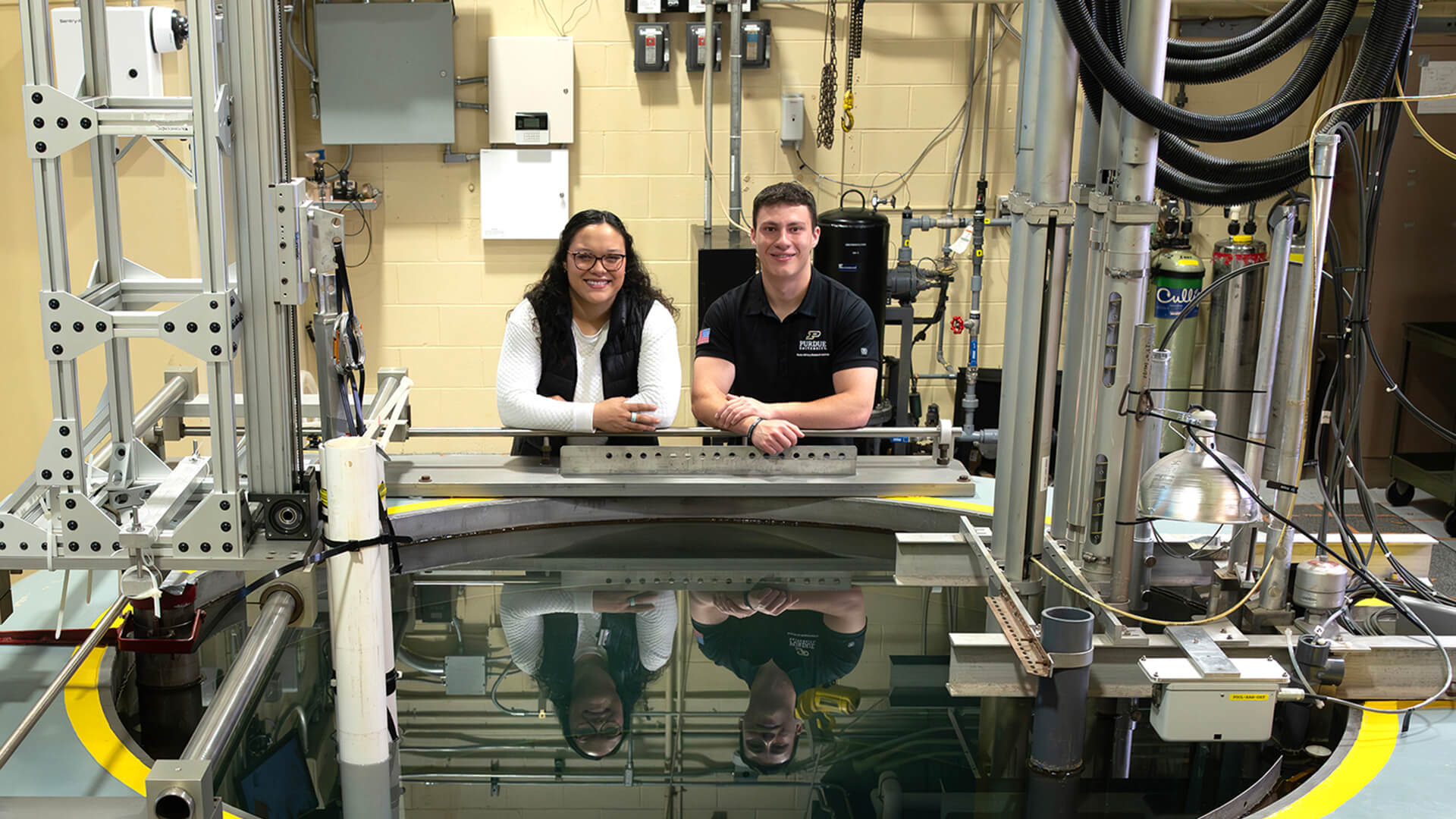

Boilermakers (from left to right) Nathan Moore, Dave Burchard, Tony Eisenhut and Mike Dilts are part of the Shiel Sexton team organizing the building of two Olympic swimming pools inside Lucas Oil Stadium. (Photo courtesy of Megan Ratts Photography, LLC)

Boilermakers pioneer aquatic sports innovation at historic Olympic swim trials event

On May 6, 2024, two days after a packed George Strait concert in Lucas Oil Stadium, trucks loaded full of steel, PVC piping, scaffolding and more lined up to begin the five-week process of building two pools in a place where no pool had ever been constructed before — a football stadium.

Two Olympic-sized (50-meter) swimming pools were constructed on Lucas Oil Stadium’s field for the 2024 U.S. Olympic Team Trials, marking the first time an indoor pool has been constructed in a venue of this size. The pool deck will be constructed approximately 8 feet above the existing field.

The idea to build a pool inside a football stadium is a novel one. But for four Purdue graduates who work at Shiel Sexton, the construction company leading the project management of the trials, every team involved is perfectly suited to bring it to life.

Assembling the dream team

One of the Boilermakers from Shiel Sexton working on the project is Tony Eisenhut (BS construction management technology ’90). As vice president of field operations for Shiel Sexton, he oversees everything that has to do with putting the pools into Lucas Oil Stadium and has been amazed at the coordination and collaboration that has taken place over the two years this project has been in planning.

“Every one of the entities involved in this project is the best of the best. It’s nice working with all ‘A’ players,” Eisenhut says. “If you wanted to build an all-star team, they are all in Lucas Oil today. And you’ve got to have Boilermakers on the team, or we would be behind schedule right now.”

Shiel Sexton regularly works closely with Indiana Sports Corp., a non-profit organization that brings world-class sporting events like USA Swimming LIVE to Indiana. Shiel Sexton collaborates with representatives from Lucas Oil Stadium, Myrtha Pools, Dodd Technologies Inc., Spear Corp. and countless others with a stake in bringing the Olympic swim trials to Indianapolis.

According to Shiel Sexton CEO Mike Dilts (BS construction management technology ’81), Purdue’s role in the Olympic Trials began 20 years ago when former Purdue athletics director Morgan Burke and former Purdue administrator Nancy Cross stepped up to pledge Purdue’s support for the 2004 FINA World Swimming Championships.

That year, Gainbridge Fieldhouse (then Conseco Fieldhouse) in Indianapolis was the first major indoor sports venue to be transformed into a swimming facility. Shiel Sexton worked on that project alongside the Indiana Sports Corp. Twenty years later, Shiel Sexton is once again bringing indoor swimming to Indianapolis, this time at a greater scale and with more innovation than ever before.

“There’s no precedent for putting an Olympic pool in a football stadium, much less two,” Dilts says.

If you wanted to build an all-star team, they are all in Lucas Oil today. And you’ve got to have Boilermakers on the team, or we would be behind schedule right now.

Tony Eisenhut (BS construction management technology ’90)

vice president of field operations, Shiel Sexton

Breaking a record

The swimming trials’ new location will double the seating capacity of the previous Olympic swim trials. And it’s clearly needed.

For this event, Lucas Oil Stadium will be able to house up to 30,000 swimming fans. Shiel Sexton, the Indiana Sports Corp. and USA Swimming hope to break the record for the largest indoor swim meet in history. The previous record of 25,000 was set at the 1936 Berlin Olympics.

Dave Burchard (BS civil engineering ’82), a project executive at Shiel Sexton, believes that this accomplishment will prove that Indianapolis is equipped to handle large-scale sporting events that require innovation and ingenuity.

“It will be another feather in the cap for Indianapolis, which is the Indiana Sports Corp’s goal — to continue their mission to host world-class sporting events,” Burchard says. “This is another success in that path.”

After all, Indianapolis is already the racing capital of the world. Why not become the swimming capital, too?

“Innovation comes from the front end of the project when we first said how many people could we put in this stadium — positioning these pools so that when the cameras come on, it looks like a natatorium that just happens to have 30,000 people in it,” Dilts says. “We have to think about the sight lines, the ticket pricing and the flow for viewers, officials, competitors, suppliers. There’s a little more ingenuity than you think in just the planning phase.”

Dilts says the experience will also be unique for competitors. “When those swimmers come out, it’s going to blow them away when you walk up the stairs to the newly raised pool deck and all of the sudden 30,000 people are cheering you on,” he says. “That’s going to be quite an adrenaline rush.”

Boilermakers get it done

According to Nate Moore (BS construction engineering and management ’93), there are three main challenges to be solved when it comes to dealing with the 2 million gallons of water that will end up inside of Lucas Oil Stadium.

The first challenge was how to supply the water. One fire hydrant with a fire hose borrowed from the Indianapolis Fire Dept. would pump water into the pools where it will be treated to the highest standards to make it safe for swimmers.

Not only will the water be professionally cleaned, but it also needs to be heated to the necessary temperature. According to standard regulations, Olympic swimming pools must be between 77 degrees and 82.4 degrees Fahrenheit. In the end, the most cost- and energy-effective solution Shiel Sexton and team developed for this challenge was to use Lucas Oil Stadium’s existing hot water heating system with two new dedicated heat exchangers.

The third challenge related to the water comes after the Olympic trials are over and the pools are deconstructed. The water needs to be dechlorinated and returned to the Indianapolis water system — now cleaner than when it started. Because of this approach, the 2024 U.S. Olympic Team Trials will be a zero-water-loss event.

Each of these challenges requires strategic thinking, innovation and expert planning — skills that the Boilermakers at Shiel Sexton credit to their Purdue education.

Lessons learned from Purdue

“Purdue taught me how to solve problems like this,” Moore says.

Burchard agrees. “Problem solving was a big part of my education. It’s a constant process,” he says. “And now it’s what we do on a daily basis.”

Dilts says that Purdue opened doors for him that wouldn’t otherwise have been available. He says, “You could go anywhere in this country and if you say you have a Purdue degree, especially in engineering and construction, there’s a level of street cred.”

And Eisenhut still holds on to a piece of advice that a professor gave him during his time at Purdue: “You don’t have to know everything. You just need to know where to find it.”