Creating a career in robotics design through an internship opportunity

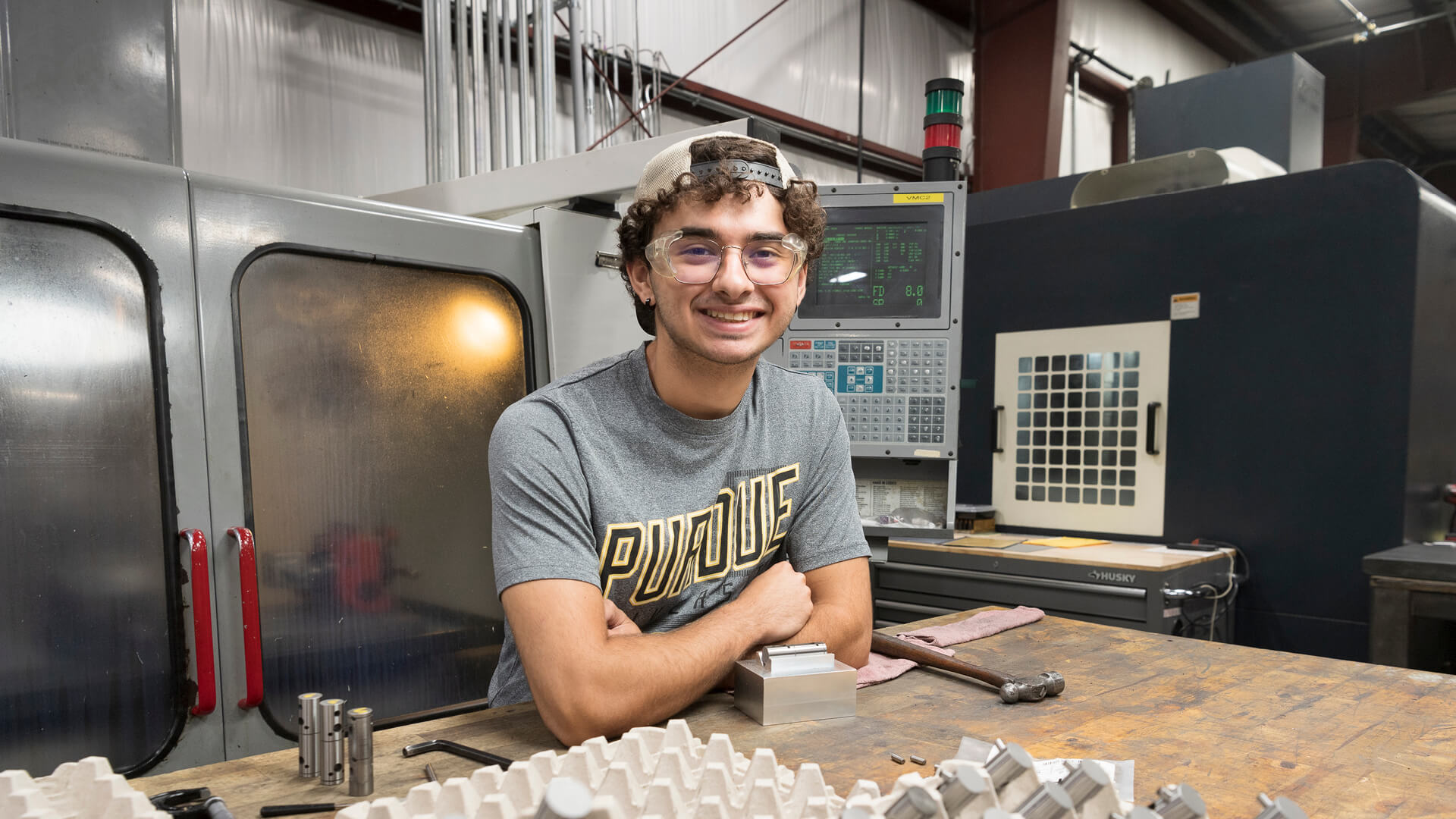

Keenan McKibben, a sophomore in Purdue Polytechnic Institute, has gained STEM experiences through his education and an internship. (Purdue University photo/John Underwood)

Purdue Polytechnic High School grad integrates engineering and manufacturing

A lifelong passion for STEM disciplines led Keenan McKibben to enroll at Purdue Polytechnic High School Schweitzer Center at Englewood, where he was a member of the first cohort of graduates. Through a summer internship, he applied the skills he learned at PPHS and stepped closer to achieving his dream of a career in robotics design.

Now a sophomore at Purdue University majoring in robotics engineering technology in Purdue Polytechnic Institute, McKibben recently interned with Rapid Prototyping and Engineering. The Franklin, Indiana-based company designs and manufactures prototype parts for companies such as Cummins Inc., Allision Transmission, IndyCar racing teams and, occasionally, NASA.

“People say that it’s not the engineer’s job to know what the machinist does, but I don’t think that’s true,” McKibben says. “I think a good engineer will have an understanding of the manufacturing process and take that into account while designing.”

I think a good engineer will have an understanding of the manufacturing process and take that into account while designing.

Keenan McKibben Sophomore, Purdue Polytechnic Institute

At Rapid Prototyping, McKibben worked with SOLIDWORKS software to design parts and generate prints. Then he followed the part he designed through the manufacturing process to ensure it was capable of functioning as intended.

Will Harvey, a 1999 Purdue mechanical engineering graduate and co-owner of Rapid Prototyping, developed his interest in designing parts after spending hours in the machine shop of the Mechanical Engineering building on campus. Offering internships to students like McKibben helps build the next generation of engineers with a better understanding of manufacturing.

“Machining parts yourself gives an engineer a fundamental understanding of what it takes to actually make something,” Harvey says. “It’s a practical application of what you’re drawing on the computer screen. A business like ours is very hands on. One part of the role is innovation and design, but you must also be able to visualize how all the elements will combine to create a functional part.”

At PPHS, McKibben was a founding member of both the VEX Robotics and FIRST Robotics teams, allowing him to develop skills to design and build machines. The school’s makerspace includes a CNC (computer numerical control) mill that McKibben and his classmates used to produce parts for their robots.

“Although on a much smaller scale than what I’m doing now, the opportunity to use the PPHS makerspace to create blueprints and either cut or 3D-print the parts we needed for robotics established a good baseline for my knowledge of manufacturing and engineering,” McKibben says. “I hope to one day work with robotics or in the additive manufacturing industry, and my Rapid Prototyping internship is paving the way for me to understand how to work with the machinists I’ll be designing parts for.”

The project-based learning cycles at PPHS — which included designing a video game, experimenting with hydroponics and building robots for a sumo match — enabled McKibben to engage with different disciplines and explore his interests before deciding on a college major. McKibben also appreciated the smaller class sizes and inclusive environment of PPHS.

“PPHS gave me the time management and self-reliance skills needed to succeed in college,” McKibben says. “When I first started at PPHS, I wasn’t sure I wanted to go to Purdue, but seeing how dedicated everyone at Purdue is to improving Indiana and bettering the entire world made me want to become a Boilermaker.”

PPHS gave me the time management and self-reliance skills needed to succeed in college.

Keenan McKibben

Sophomore, Purdue Polytechnic Institute

McKibben is looking forward to taking more classes in his major and living in an off-campus apartment. He also plans to increase his involvement with clubs and student organizations. Looking back, McKibben is grateful for his experience at PPHS, which set him on the path to Purdue.

“I can’t imagine not being a Boilermaker,” he says. “Attending PPHS made me who I am.”