Boilermakers have changed the way the world eats

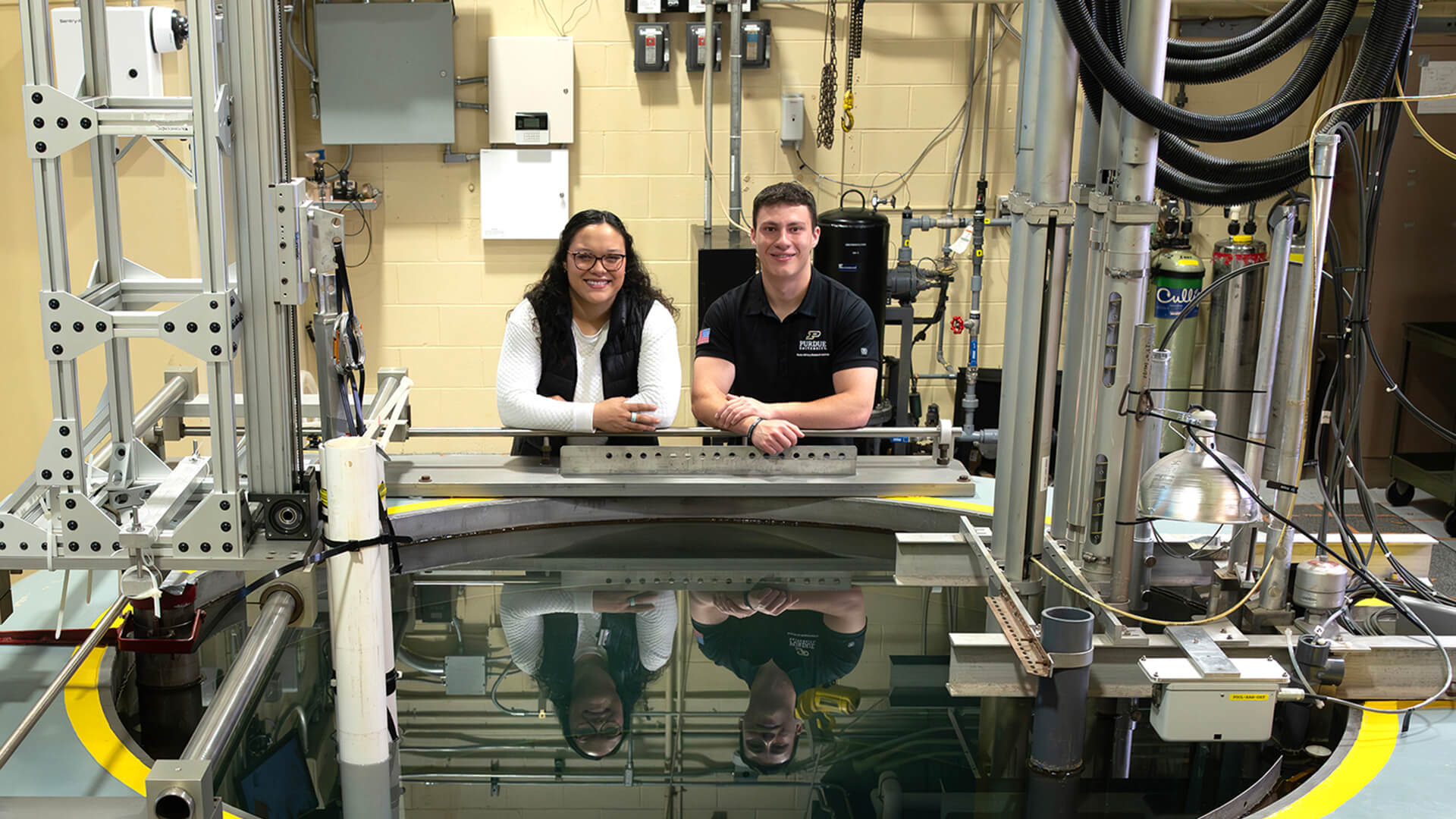

Scientists from Purdue have created new varieties of foods and pioneered growing methods, while improving food safety, security and sustainability. (Purdue University photo/Rebecca Robinos)

Food innovations instigate progress, from farming to product packaging

It’s difficult to picture what grocery stores, restaurant menus and dinner plates would look like without innovations from Boilermakers. Industries have stemmed from the inventions and improvements established by these leaders taking giant leaps in food science.

“It’s chemistry, it’s microbiology, it’s engineering, it’s packaging. All this goes into making a food product,” says Amanda Deering, associate professor of produce food safety in the College of Agriculture, during an episode of “This is Purdue.” “And so we are an interdisciplinary program. We have to be.”

Deering shared Purdue’s ongoing advancements in food safety, security and sustainability in the conversation with Haley Oliver, the assistant dean of Ag Online Programs, 150th Anniversary Professor of Food Science and director of the U.S. Agency for International Development’s Feed the Future Innovation Lab for Food Safety. Alongside their colleagues and current students, they’re working with researchers around the world to continue the university’s legacy as a front-runner in food innovation.

It’s chemistry, it’s microbiology, it’s engineering, it’s packaging. All this goes into making a food product.

Amanda Deering Associate professor of produce food safety

Master Mix and Stove Top stuffing

Food pioneers at Purdue have been helping households make memorable meals — all while saving time and effort — since the 1930s. Two formulations, Master Mix and Stove Top stuffing, ingeniously combined ingredients to create faster, foolproof ways to cook, forever changing the way families approach both weekday dinners and holiday celebrations.

Gertrude Sunderlin began teaching in the College of Home Economics Experimental Foods Department in 1931. She came to Purdue after earning a bachelor’s degree in home economics and a master’s in household bacteriology from Iowa State University. After becoming the first woman to receive a PhD from Iowa State, she brought her extensive knowledge of the science behind safe nutrition to West Lafayette.

Stove Top stuffing was invented by Purdue alumna Ruth Siems while she worked at General Foods as part of their research and development staff. (Purdue University photo)

During the 23 years she taught, Sunderlin oversaw the development of inventions integral to today’s food culture. One of these breakthroughs was the forerunner to commercial baking mixes. In a time before grocery store shelves were stocked with every sort of boxed biscuit, cake, cookie and muffin base, her laboratory created Master Mix, a combination of flour, baking powder, salt, cream of tartar, sugar and shortening that revolutionized kitchen time-saving techniques.

Master Mix made its national debut in a 1947 issue of Better Homes & Gardens magazine, gaining instant popularity and creating the need for Purdue Extension to print 75,000 copies of its initial bulletin to share the recipe over the next five years. It transformed bakers’ approaches.

“The Master Mix recipes are time savers and reputation builders,” Sunderlin wrote at the top of the bulletin. “The siftings and measurings of the dry ingredients and the blending of the fat can be done at one time for a dozen bakings.”

Ruth Siems, one of Sunderlin’s students, created a recipe which is owned today by one of the world’s largest food and beverage companies, Kraft Heinz. Siems, the inventor of Stove Top stuffing, earned a bachelor’s in home economics from Purdue in 1953. The stuffing — in that signature red box holding a five-minute method to prepare a classic side — took continual trial and error but was finally granted a U.S. patent in 1975.

That patent captured the secret to the successful recipe: “The nature of the cell structure and overall texture of the dried breadcrumb employed in this invention is of great importance if a stuffing which will hydrate in a matter of minutes to the proper texture and mouth feel is to be prepared.” Siems determined the perfect breadcrumb dimension and produced a dish that, decades later, sells about 60 million boxes a year.

Orville Redenbacher and popcorn seeds

Boilermakers have led the way in all kinds of food industries, including forming a prolific Purdue popcorn legacy. Among the scientists who have specialized in originating hybrid seed varieties is Orville Redenbacher, whose products and media influence established his reputation as a household name.

Redenbacher was active across campus in West Lafayette while earning a bachelor’s degree in agronomy; joining the Alpha Gamma Rho fraternity; playing in the “All-American” Marching Band; and editing the Debris, the Agriculturist and the Purdue Exponent publications. After graduating in 1928, he worked as an agricultural agent and organizer, eventually forming the company Chester Hybrids alongside fellow Purdue alum Charles Bowman.

Chester Hybrids became a top producer of popcorn seeds and supplies, aiming to engineer a lightweight, fluffy corn that would pop consistently. For years they planted, tested and cross-pollinated seeds until they found the winning product and began selling gourmet popping corn in 1970. The superior seeds, in combination with Redenbacher’s resonating persona, led to instant success.

Sixty years after graduating, Redenbacher received an honorary doctorate in agriculture. Throughout his career, he remained a dedicated alum, attending football games annually and starting a scholarship for nontraditional students. He is part of a host of involved instigators who have made progress in hybrid popcorn methodologies at Purdue, including researchers at a leading supplier of popcorn seeds.

Whether it’s at a theater, out of the microwave, or pre-popped in a bag and ready to eat, popcorn products across the U.S. have ties to Purdue. In 1938, Purdue alumni started Ag Alumni Seed, an affiliated commercial seed breeder and distributor. The company expands the research of popcorn geneticist Bruce Ashman and strives to perfect their products, from the plant’s yield rate and disease resistance to the popped corn’s expansion ratio and aroma.

Chicken nuggets

Here’s a whole new reason to be proud to be a Boilermaker. It’s difficult to imagine a celebration without boxed baking mixes or a movie night without popcorn. But it’s difficult to imagine life in general without another alum’s invention: chicken nuggets.

Chicken nuggets! Prior to the 1950s, there was no successful way to get breading to stick to the chicken, and such poultry products could not be produced at an industrial scale. Consuming chicken was complicated, time-consuming and messy. Birds were usually bought whole and had to be oven-roasted or pan-fried, an all-around inconvenient process.

Robert C. Baker, who earned a doctorate from Purdue, created the recipe for breaded chicken that could be distributed, reliably cooked and enjoyed. The prototype nugget was the result of experimenting with ground meat, powdered milk, pulverized grains, egg batter and cornflake crumbs, all undergoing a strategic freezing process. In the end, the research permanently altered what was on people’s plates from restaurants to residential dining halls.

Not only was Baker a chicken nugget pioneer, he was responsible for the creation of chicken hot dogs, chicken cold cuts, turkey hot dogs, turkey ham and ground poultry. He also helped design packaging to improve the chicken shipping process.

Before receiving his doctorate in food science, Baker earned a bachelor’s degree in pomology at Cornell University and a master’s degree in marketing from Penn State. After returning to Cornell to become a professor, he founded Cornell’s Institute of Food Science and Marketing and published over 290 research papers in his field.

Apple varieties

Purdue’s reputation as a leader in agricultural education stems from many decades long initiatives that continue to build on well-established research. One of the university’s notable pursuits is its improvement of apple genetics, leading both to new varieties and better growing methodologies.

Decades of research have resulted in Boilermakers’ internationally recognized expertise on apples. (Purdue University photo/Rebecca Robinos)

A partnership among Purdue, Rutgers University and the University of Illinois — named PRI — was formed in 1945 to develop disease-resistant apples. PRI focused on breeding plants resistant to apple scab, a fungal disease that damages the leaves and fruit. The program has brought together some of the nation’s leading horticulturists, including apple geneticist Jules Janick.

Janick earned a Purdue master’s and doctorate before becoming a professor in the College of Agriculture. During his 69 years of service to Purdue, he edited groundbreaking horticulture publications and oversaw the success of six utility patents and 23 plant patents, including apple varieties such as CrimsonCrisp, Enterprise, GoldRush, Juliet and Pixie Crunch.

Not only are these varieties popular around the Midwest, but they’re found in orchards around the world, with the Juliet particularly catching on in France. The pros of a Juliet apple? For growers, they’re disease-resistant and have a long storage life. For consumers, they’re shiny, crisp and resistant to fruit browning.

At Throckmorton/Meigs Purdue Agricultural Center, located about 10 miles south of Purdue’s flagship campus in West Lafayette, over 200 different apple genotypes are grown for research. Purdue programs today aim to improve growing methods and ultimately help the way all growers care for apple orchards.

Soft serve ice cream and sweet new flavors

Ending on a sweet note: The first patented soft serve ice cream machine was created by Frank Thomas Jr., who graduated from Purdue with a degree in mechanical engineering in 1941. He was able to perfect the freezing and agitating process with his machine and produce the popular dessert.

Thomas was an inventor and entrepreneur in the food industry. Additionally, he helped create a grill to flame-broil patties — that prototype grill was made for James W. McLamore and Dave Edgerton, the founders of Burger King.

To distribute his soft serve ice cream machines and flame-broiling equipment, Thomas founded the General Equipment Company. In 1957 he opened a demonstration store for his company’s products, running the location alongside his brother and fellow Purdue alum Donald Thomas.

The store’s success spurred the creation of the brothers’ restaurant chain, Burger Chef. Burger Chef grew to more than 1,000 locations and was sold to General Foods, then eventually owned by Hardee’s.

Other recent ice cream innovations at Purdue have resulted in the development of a new flavor created by students from the Food Entrepreneurship and Manufacturing Institute in the College of Agriculture. President Mung Chiang encouraged the creation of a new flavor and personally taste-tested recipes. Boiler Gold Rush students and group leaders also helped test and voted for the winning flavor’s fitting name: Boiler Chips.

With the production help of Glover’s Ice Cream, Boiler Chips is being packaged in eight-ounce retail cups for the Purdue Memorial Union Boilermaker Market and Purdue Food Co.’s catering. An additional flavor, One Giant Scoop, uses the original vanilla recipe from the Purdue University Creamery, which ran for decades in Smith Hall.

It’s a full-circle moment. When the Purdue University Creamery closed in 1969, it passed on its formula to Glover’s. The Frankfort, Indiana-based company then made flavors for Pappy’s Sweet Shop, a favorite spot in the Union from 1927 until 2020. Now, the beloved recipe is back on campus in 2023. A portion of Boiler Chips and One Giant Scoop sales will fund professional development opportunities for food science students.