Chance encounter reveals Purdue engineers’ remarkable connection

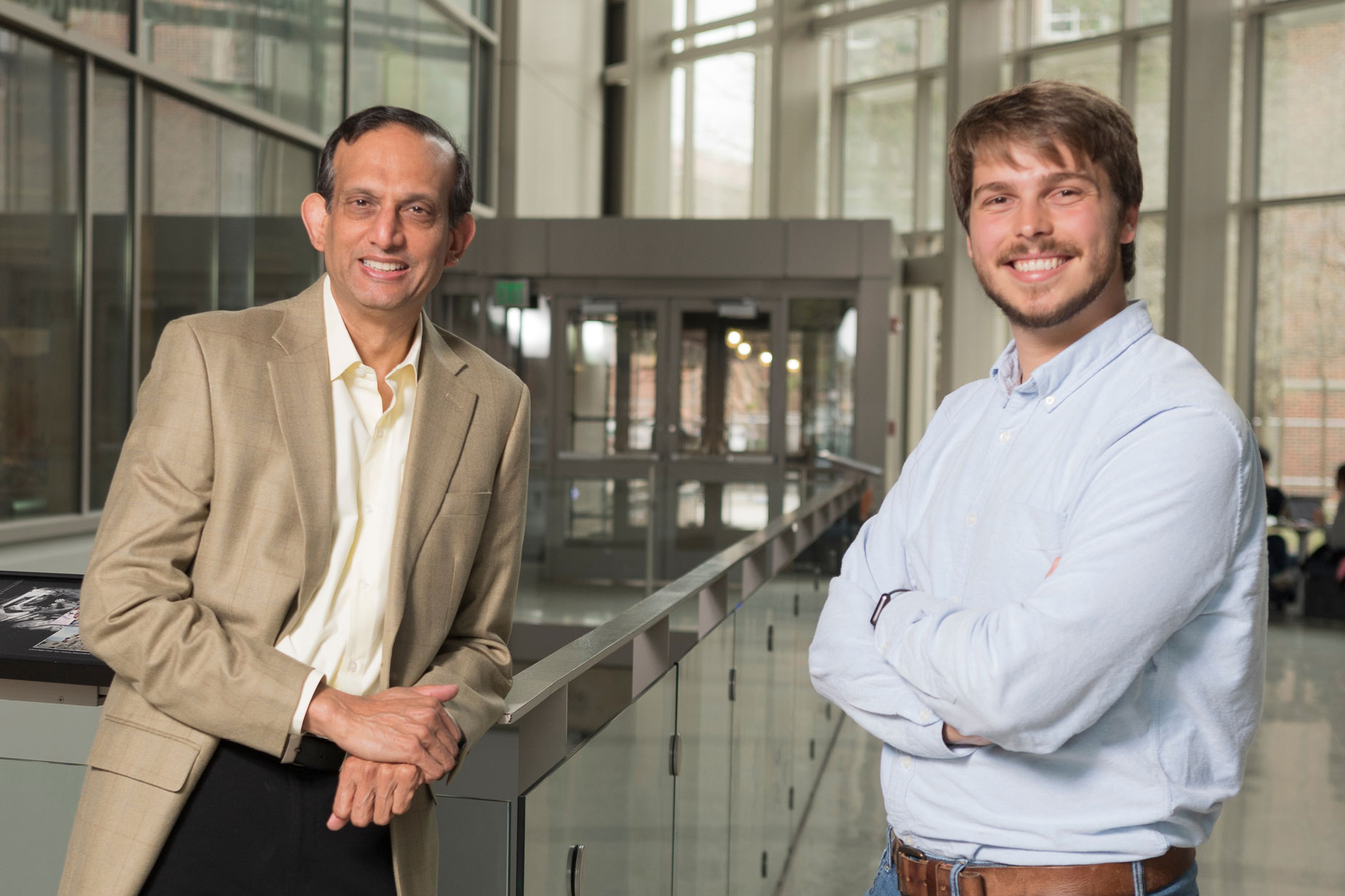

Logan Noster, left, and Cook Biotech President Umesh Patel, right, learned of their shared connection when they met before an awards banquet in February. (Photo by John Underwood/Purdue Marketing and Communications)

New graduate Logan Noster was among the first infants to receive the SIS grafts that Cook Biotech President Umesh Patel helped develop at Purdue

In the 27 years since he became the second employee of Cook Biotech, Umesh Patel has met only a handful of the 6 million patients who benefited from the company’s revolutionary innovation that he helped introduce.

Now the company’s president, Patel certainly did not expect to meet such a person on the day that Purdue’s multidisciplinary engineering (MDE) program recognized him as its 2021-22 outstanding alumnus.

Nor that this person would be a Purdue student who shared the same engineering major and would also be recognized that night as one of the program’s outstanding seniors.

Nor that this young man had been one of the first infants ever treated with Cook Biotech’s small intestinal submucosa (SIS) grafts, which helped close a ventral hernia on his abdomen – the result of a rare birth defect.

But when he met Logan Noster, all of this was the case.

Logan Noster met Cook Biotech’s first two employees, Michael Hiles and Umesh Patel, at the Purdue multidisciplinary engineering program’s awards banquet in February. (Photo courtesy of Teresa Walker/Purdue School of Engineering Education)

“What are the odds that something like that would happen, this chance encounter?” Patel asks. “When you think about it, this is a technology invented at Purdue University and licensed to Cook, an Indiana-based company. Cook Biotech was started here in Purdue Research Park. That SIS was able to be used to help a baby that lives in Indiana and he grew up to attend Purdue, it’s amazing.”

The experience was equally amazing to Logan and his parents, Keith and Linda, who traveled to campus that night to celebrate their son’s academic achievements at the banquet.

It had been more than two decades since Logan’s traumatic first year, which involved three surgeries after he was born with an omphalocele – his liver was located outside of his body upon delivery. Doctors at the time told the Nosters that only one in approximately 8,000 babies dealt with this condition.

Naturally, their meeting with Patel and his Cook Biotech colleagues – including the company’s first employee, Michael Hiles, another Purdue graduate – reminded them of the fear and anxiety that hung over most of the pregnancy after doctors identified the omphalocele during an early ultrasound. It was also cause for gratefulness, as they were able to cheer their high-achieving son’s success and otherwise perfectly normal life alongside researchers whose innovation helped Logan avoid a series of additional early surgeries.

“It was surreal. It was like full circle,” Linda Noster says. “And then to actually meet him, and he was so generous about his feelings that he met one of the first pediatric patients to receive his technology. It was almost like there was already a bond between him and Logan.”

Patel has heard many success stories through the years involving the 6 million patients who have received SIS grafts. But this one hit close to home for the company president and his colleagues at the banquet.

Standing before them was a tremendous success story from their very own backyard.

“They do this to help people,” Logan says. “They love hearing patients’ stories, so being able to share my story with somebody who created the technology that has been life-changing for me, that was a really cool experience.”

Meeting in ‘The Nest’

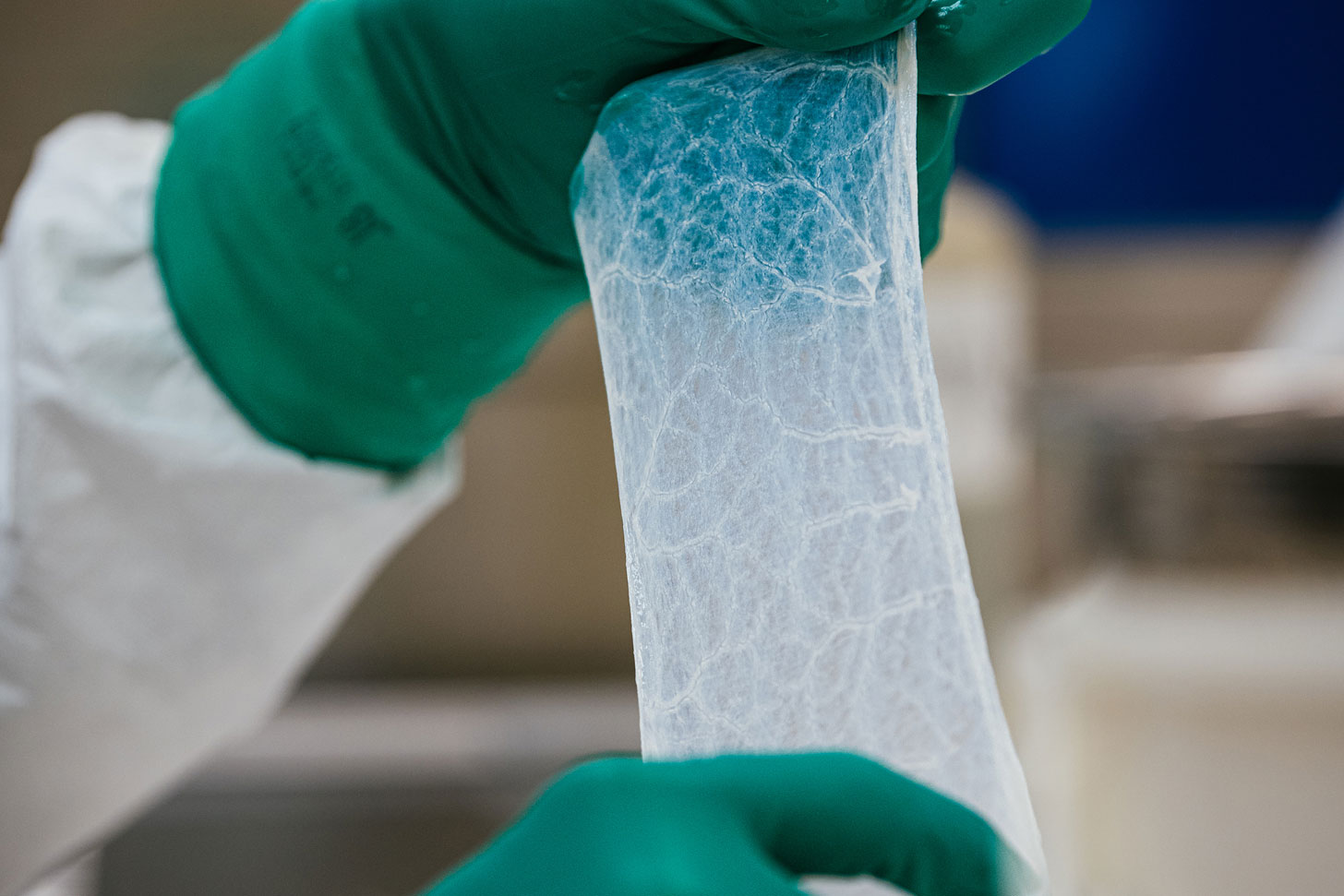

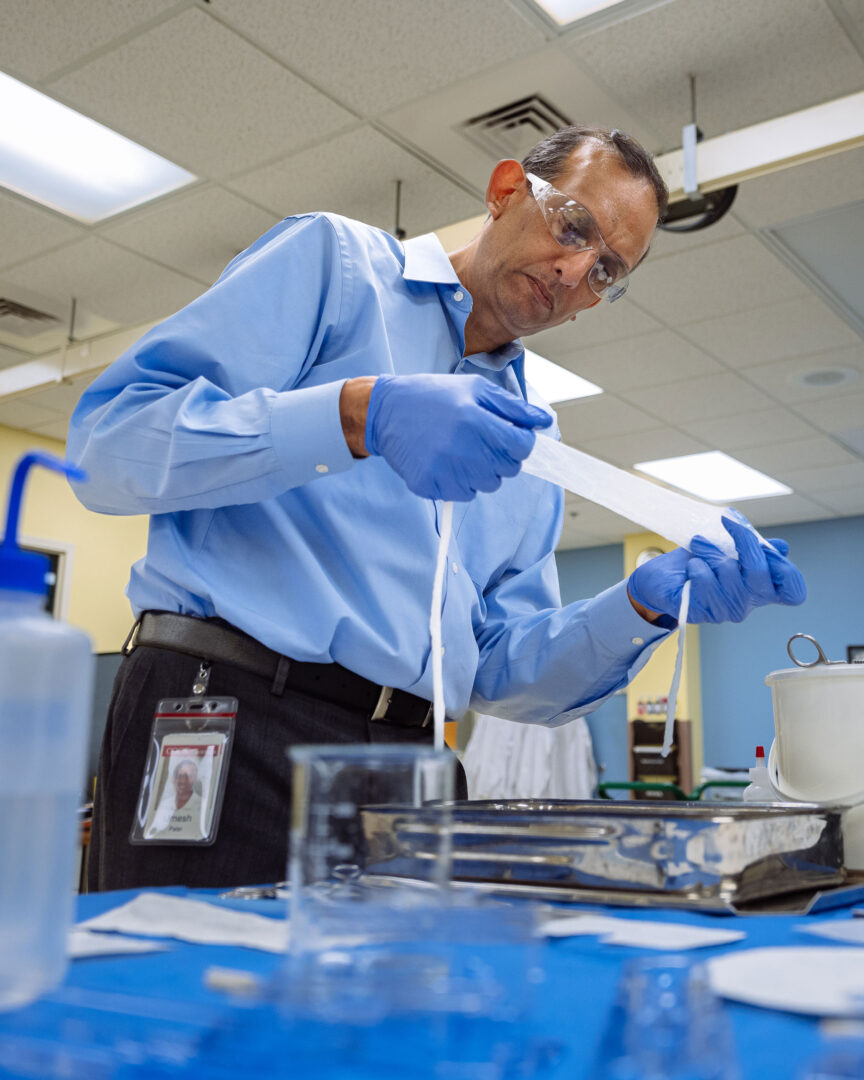

Their initial meeting was indeed a chance encounter, on the afternoon of the Feb. 21 awards banquet. While visiting with MDE student awardees in their study space at Neil Armstrong Hall of Engineering, affectionately dubbed “The Nest,” Patel described how SIS works. Made from the durable inner layer of a pig’s small intestine, SIS can be surgically implanted to spur tissue growth in a variety of medical situations – from hard-to-heal wounds to burns, nerve damage, diabetic foot ulcers or a hernia like Logan’s.

“It will act as a scaffold, bring in the appropriate tissue, and then over time, it’s gone,” Patel says. “It’s just the patient’s own natural tissue that replaced the hernia. The other option was to use a synthetic material that would remain inside but not grow with the patient, which would require follow-up surgeries.”

That day in “The Nest,” Logan didn’t know many specifics about his December 2000 surgery involving SIS grafts, but hearing about the product’s biological origins rang a bell.

Made from the durable inner layer of a pig’s small intestine, Cook Biotech’s SIS grafts are used to treat an ever-expanding list of medical ailments. (Photo by John Underwood/Purdue Marketing and Communications)

“I didn’t know there was a fancy word for it like SIS, but I always knew they used pig material to kind of graft over that muscle,” says Logan, a graduating senior in MDE with a concentration in visual design engineering.

When Logan spoke up about potentially having been treated with SIS as an infant, it visibly caught the distinguished alumnus off guard.

“All the other students were like, ‘Huh. Interesting. He had that done,’” recalls Mary Pilotte, director of engineering education undergraduate degree programs. “It was real subtle, real casual, but you could see Umesh’s eyes, like, ‘That procedure? You had that procedure done?’ It was going through his mind, for sure, but I don’t think the students really realized the magnitude of the discovery in that moment.”

Logan called his mother immediately after meeting Patel, and she said that SIS had indeed been used during the surgery. To be absolutely certain, Logan also requested his surgical records from Indianapolis’ Riley Hospital for Children, where the surgery had been performed.

“I didn’t want to get too excited about it after that discussion with Umesh,” Logan says. “But after going through my medical records, you can see right there, plain as day: ‘Cook Biotech small intestine submucosa graft was used to cover up the ventral hernia.’ So, 100% it was his technology and his team’s breakthroughs that helped me become the person I am.

It was his technology and his team’s breakthroughs that helped me become the person I am.

Logan Noster

BS multidisciplinary engineering ’22

“It’s really a testament both to modern technology and to the resilience of the human body. They’re not putting any sort of miracle drug in you. They’re exploiting your own body’s ability to heal, which is amazing what the body can do with a little help from some pig intestines.”

Challenging first year

Back in 2000, the Nosters had every reason to worry about what might become of their son – starting the day when they were informed that their baby would be born with an omphalocele.

When they first received the news, approximately six weeks into the pregnancy, neither Keith nor Linda had ever heard of an omphalocele. But they knew this much:

“Immediately, it registered that this ain’t good,” Keith says.

Linda had to switch to a doctor who specialized in high-risk pregnancies, and she underwent a battery of tests to determine whether Logan would have Down syndrome or other potential issues with his heart, eyes or respiratory system.

Over time, the medical staff was able to rule out these potential outcomes. When Logan was delivered three weeks early on March 31, 2000, his omphalocele – while serious – was his lone physical issue.

Linda had not expected to be able to hold Logan following the delivery. When the nurses surprised her by placing him in her arms, the sense of relief was overwhelming.

“I cried,” she says. “I think [Keith] cried, too, because you’ve had eight months to anticipate the worst, and it was the best. We were able to hold him, and he was screaming his head off, so we knew he had good lungs. And they had assured us that they eliminated everything. What was wrong with him was the omphalocele, and they would be able to repair it.”

Prior to the delivery, Logan’s doctors estimated that he would be in intensive care for six weeks. He actually left the hospital after only nine days.

However, the family knew that a trying first year was still ahead.

Describing Logan’s three surgeries in his first year as “terrible” and “really scary,” Linda jumped at the opportunity when trusted Riley surgeon Scott Engum suggested that using SIS to repair Logan’s hernia would likely reduce the need for even more surgeries.

“As many surgeries as he had to go through, it’s just terrifying when you’ve got a baby and they’re in this little bed going through this. If we can eliminate any future surgeries on his gut, we were going to do that,” Linda says.

Patel also marvels at the medical staff’s foresight. The FDA approved SIS to treat wounds in 1998 and for hernia repair and soft-tissue reinforcement the following year. But it was still a brand-new option within the world of pediatrics.

“The surgeons at Riley are amazing to do that and to have the knowledge base to say, ‘Hey, this technology could probably help him and close the defect that he had left,’” Patel says.

Logan emerged from that difficult first year as a perfectly normal child, aside from the scar on his abdomen where a belly button should be.

“I kept saying, ‘Logan, that is your badge of honor,” Keith says. “You went through more than many people do in a lifetime in your first few years of life.’”

A budding engineer

The Nosters figured they had an engineer on their hands when Logan was only 3 or 4 years old because of his penchant for building things using printer paper, tape and safety scissors. When he graduated to Legos, Thomas the Tank Engine train sets and Star Wars toys, his construction projects became increasingly elaborate.

Once he reached middle school, Logan enthusiastically joined a STEM-oriented educational program, Project Lead the Way, that cultivated his interests via fun projects like using a 3D printer, building a hovercraft, experimenting with computer-aided design and creating an energy drink.

“Being able to join that program and see what’s out there and unlock a part of the problem-solving part of my brain that I’d never really exploited before was hugely beneficial,” Logan says.

The projects became more complex when he remained in the program as a student at Indianapolis’ Lawrence North High School. One block away from the high school was the McKenzie Center for Innovation and Technology, where Logan and other Project Lead the Way students attended some classes.

Gaining practical experience under the watchful eye of teachers who had worked in multiple engineering fields significantly enriched his learning. Majoring in engineering at Purdue felt like a no-brainer by the time Logan was participating in a design verification internship at Roche Diagnostics as a Lawrence North senior.

While testing the company’s blood glucose meters and their packaging, compiling data and making engineering judgments, Logan began to recognize that other avenues are available to engineers beyond tried-and-true routes like civil engineering, which he initially expected to be his major at Purdue.

When a group of multidisciplinary engineers – including a visual design engineer – described their various concentrations to students in one of Logan’s first-year engineering classes, he had found his calling.

He excelled within the MDE program, earning recognition as one of its outstanding juniors in 2021 and seniors the following year.

“It gave me the freedom to take more computer graphics courses, to do more visual learning and visual communication-type coursework, which I think hugely benefited me in my ability to rise through the ranks as an engineer,” Logan says. “What that freedom results in is people who think differently than your common engineer.We kind of have a mixed bag of people with all sorts of different skill sets and abilities that you won’t find in any other major.”

He didn’t know it when he selected a multidisciplinary engineering pathway, but Logan was following in the footsteps of the researcher who helped create the SIS technology that benefited him as an infant.

Patel expected to become a physician when he enrolled at Purdue, but instead opted to become a biomedical engineer capable of speaking multiple engineering languages. After earning an undergraduate degree in interdisciplinary engineering, Patel completed a master’s degree in electrical engineering and a PhD in industrial engineering, all while working under legendary mentor Leslie A. Geddes in Purdue’s Hillenbrand Biomedical Engineering Center.

“As a biomedical engineer, you need to understand a variety of different disciplines,” Patel says. “I think that’s where the magic comes, also, in inventing things. If you have these knowledge bases in other areas and can talk to people in different disciplines, you can wonder, ‘Oh, can that apply to this problem I’m trying to solve?’”

Engineers solve problems

Solving problems is among the aspects of their profession that the two Boilermaker engineers love most.

Patel jokes that there is never a dull moment at Cook Biotech, where new uses for the company’s technology consistently emerge.

“SIS has applications from head to toe, and there are still applications out there being created,” he says.

Meanwhile, Logan will start his first job in June, just a few weeks after graduating from Purdue. He will work at the Naval Nuclear Laboratory in Pittsburgh, designing test equipment for the reactors at Bettis Atomic Power Laboratory.

On his first job interview with his new boss, Logan explained that what he loves about engineering is not the math or science that it entails. It’s addressing the problems that engineers are equipped to solve.

“That’s what this ability to kind of make my own major has done for me,” Logan says. “I’m able to take so many more design and manufacturing courses that have set me up to think in a way that I don’t just do equations. I can look at a problem and come up with five or six different solutions and go test those and come back and report on how those all worked.

“Because those are all things I’ve done. Whether in an internship or a class or a club I’ve been in, I’ve got the communication skills and the technical skills necessary to solve these complex engineering problems, and I think that’s what being a Purdue engineer is.”

Patel credits his own Purdue engineering background – and particularly the influence of faculty mentors Geddes, Gavriel Salvendy and W. Dale Compton – for helping him take the many giant leaps that led him to the prominent position he now occupies.

“I don’t know that I would have had that combination of mentors anywhere else,” Patel says. “It has really served me well, all three of those mentors and what they taught me in my career.”

It should come as no surprise that this well-rounded mentorship was available to a Purdue multidisciplinary engineer. These practitioners approach their fields a bit differently, sometimes yielding unexpected results. If the chance meeting between Patel and the Noster family was to happen anywhere, of course it was within Purdue’s MDE program.

“You would think that it’s coincidence, but somehow it starts to feel like we’re some sort of cosmic vortex here and these unique instances just come,” Pilotte says. “This is Purdue. It attracts these situations that are super special.”

This is Purdue. It attracts these situations that are super special.

Mary Pilotte Director, engineering education undergraduate degree programs