Seeing STARS: Purdue trains next generation of semiconductor engineers

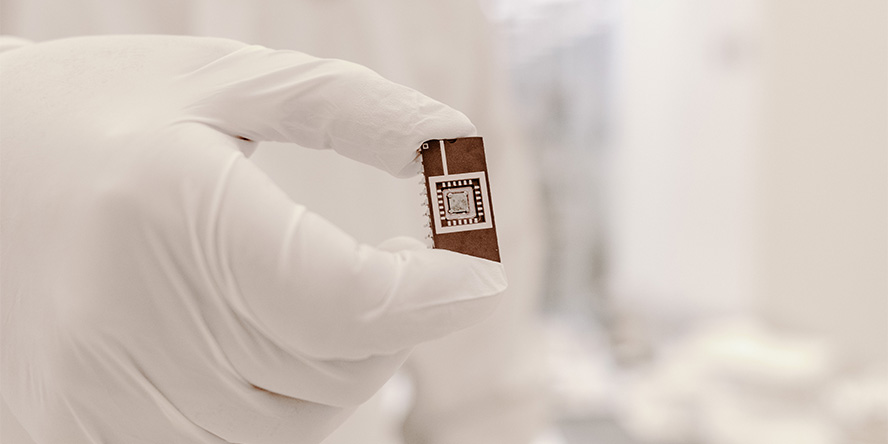

Purdue started the Summer Training, Awareness and Readiness for Semiconductors (STARS) program this year to jump-start students’ training for careers in the semiconductor industry. (Purdue University photo by John Underwood)

Hands-on summer program prepares students to contribute as interns

As their campus tour wound its way through Purdue’s Birck Nanotechnology Center, Raygan Bingham and her mom peered through the windows of the facility’s semiconductor cleanroom.

Inside, workers were decked out from head to toe in protective “bunny suits” designed to prevent particles from disrupting the fragile semiconductor manufacturing process. Their work environment in the Scifres Nanofabrication Laboratory, a cleanroom designed to keep even tiny particles to an absolute minimum, looked so important. So scientific.

It was far beyond what Bingham could picture herself doing.

“I never once thought that I would get the chance to be in there and get to do that,” says Bingham, a sophomore from Cincinnati majoring in mechanical engineering. “I guess it just felt very intimidating.”

Through initiatives like the STARS program, Purdue is helping to grow the U.S. semiconductor workforce

And yet, with only two semesters at Purdue under her belt, she found herself working in that very cleanroom environment. Between May and July, Bingham was among 72 Boilermaker students who participated in the Summer Training, Awareness, and Readiness for Semiconductors (STARS) program, designed to jump-start their training for careers in the semiconductor industry.

“Without this program, I don’t think I would have ever really thought to go into this industry, even though it is becoming so big,” Bingham says. “Seeing the opportunities that it will open up for students will be amazing because there are so many different directions you can go. It would be absolutely incredible to be part of the semiconductor industry.”

Inspiring more students to share Bingham’s newfound perspective is vital because U.S. semiconductor engineers and researchers have never been more necessary than they are today.

The U.S. needs an estimated 50,000 new semiconductor engineers over the next five years to meet the escalating need for increased computing power. That need will only accelerate in the coming years, thanks in large part to the 2022 CHIPS and Science Act, which will inject approximately $280 billion into the domestic semiconductor industry to support research and manufacturing.

In response to this pressing national issue, Purdue has taken a leadership role by introducing the first comprehensive semiconductor degree program in the U.S., forging innovative partnerships with industry partners and foreign governments, and launching ambitious experiential initiatives like STARS.

Without this program, I don’t think I would have ever really thought to go into this industry, even though it is becoming so big.

Raygan Bingham Sophomore in mechanical engineering

“Purdue is really being the role model,” observes Dilay Aygun, a junior from Turkey majoring in computer engineering. “I don’t think any other universities are taking this sort of action.”

It’s a role that Purdue is uniquely positioned to play. Not only does Birck feature one of the world’s largest university cleanrooms, but Purdue’s many connections to the semiconductor field stretch all the way to mechanical engineering alumnus Mohamed Atalla’s co-invention of the revolutionary metal-oxide semiconductor field-effect transistor (MOSFET) in 1959.

“We probably have one of the largest concentrations of semiconductor faculty of any university in the nation,” Mark Lundstrom, Purdue’s chief semiconductor officer, said on a June 2023 episode of the “This Is Purdue” podcast. “And it’s more challenging to do this kind of work. You need expensive laboratory facilities like the Birck Nanotechnology Center. So, it makes it difficult for many universities to have a substantial presence in this field. We’re one of the few.”

Related Stories

If the student response to Purdue’s inaugural STARS offering is any indication, the program is off to a rousing start.

Lundstrom said he would have been pleased with 50 students applying to participate. However, more than 500 Boilermakers applied, he said. “I think this is a data point for the nation,” Lundstrom said. “Students are paying attention. They’re really excited about learning more.”

‘The most consequential problem that the country currently faces’

Workforce development programs like STARS are essential as educational institutions, government agencies and industry partners collaborate to solve what Lundstrom describes as “the most consequential problem that the country currently faces.”

U.S. legislators passed the bipartisan CHIPS Act out of necessity after supply chain bottlenecks during and after the COVID-19 pandemic made it difficult for manufacturers to produce in-demand items like cars, computers and appliances. Those issues exposed major vulnerabilities regarding U.S. access to semiconductors – essential components that function as the brains of every electronic device – since just 12% of the global semiconductor supply (and none of the most advanced chips) is produced in America.

The need for immediate action grew over concerns that China might invade Taiwan, where 60% of all semiconductors and 90% of the most advanced versions are manufactured. Without access to those Taiwanese chips, U.S. economic activity would quickly grind to a screeching halt.

However, thanks to economic incentives embedded in the CHIPS Act, domestic semiconductor production will soon begin anew at fabrication plants like the $1.8 billion facility that industry partner SkyWater Technology plans to build on the edge of the Purdue campus. And the U.S. will have an opportunity to expand its foothold in chip design with initiatives like the partnership between Purdue and MediaTek Inc.

“The CHIPS Act is trying to bring foundries back to America. And if you’re going to bring more foundries back here, you need more people in manufacturing who are qualified to work in them,” says Noah Rediker, a sophomore in computer engineering from Ocean Township, New Jersey, a teaching assistant who helped create the STARS chip design track.

“And from a design perspective, the best part is that having the foundries closer to home means that everything runs faster. You don’t have to wait to ship things around the world. You don’t have to wait for meetings to happen between people on other sides of the globe. The CHIPS Act is going to make this entire field so much quicker, so much more reliable. If the world shuts down, those issues won’t happen again.”

The STARS experience

For eight weeks, STARS students put in full days of challenging, hands-on work while also building a community. Whether collectively zipping around campus on the longboards they all seemed to own, playing volleyball in the evenings or participating in some other social activity, STARS students created a support system they expect to last for the remainder of their Purdue experience and beyond.

“Coming in, I was nervous because I wasn’t sure what to expect and didn’t know many people,” says Emily Moreno, a sophomore from Chicago majoring in aeronautical and astronautical engineering. “But I got the impression very quickly that everybody was super friendly and willing to help one another out.”

Students in the chip design track – led by Mark Johnson, director of instructional laboratories in Purdue’s Elmore Family School of Electrical and Computer Engineering – underwent a crash course in circuit design and programming languages, completing the program with group projects that will allow them to test the functionality of the digital integrated circuits they designed for fabrication.

Although many of the students entered the program with very little (or no) circuit design experience, their rapid progress impressed the program’s instructors.

“That was fun to watch, but it was a lot of extra work because they were going through the material so fast during the program that I had to create extra materials,” says Phillip Walter, instructor for a two-week section on digital logic. “I created these self-paced tutorials and self-paced laboratories where they did some breadboarding, and they started going through them so quickly that I had to create some extra tutorials and mini projects. They were awesome.”

Meanwhile, those like Bingham and Aygun in the program’s manufacturing track – led by professors Muhammad Hussain, Rahim Rahimi, Thomas Beechem and Muhammad Alam – learned the basics of working in the cleanroom and developed skills related to chip fabrication and material and device characterization.

Over the course of the eight weeks, many STARS participants advanced from an extremely limited knowledge of what semiconductors are to a working understanding of how they function and why they’re important.

Still, it took a while for that intimidation factor to wear off when working with high-tech equipment designed to create microscopic electronic devices – one of the primary benefits of STARS participation.

“All of us are a little bit nervous because you’re dealing with equipment that costs millions of dollars. You don’t want to mess anything up,” Bingham said shortly after her first cleanroom experience. “But I think the cool thing about this program is that we’re almost meant to mess things up. We know we’re going to make mistakes and it’ll be OK. Like they told us today: ‘You’ll end up with kind of a bad device, and that’s going to be all right. It’s your first time in there.’ So, we’re really fortunate that before we go into industry and before we do internships in those companies’ cleanrooms that we’re able to get this experience and make mistakes.”

Among the companies where students might someday find internships or employment are the 11 organizations that served as the STARS program’s partners and benefactors:

- Cisco

- GlobalFoundries

- Intel

- L3Harris

- MediaTek

- SK Hynix

- SkyWater Technology

- Synopsys

- Taiwan Semiconductor Manufacturing Company

- Texas Instruments

- Western Digital

These companies also sent representatives to meet STARS students, explain the industry’s workforce needs, share their perspectives on what it’s like to work in the field, and describe how semiconductor innovations impact many different engineering disciplines.

“We’ve learned about how they brought their experience to the semiconductor field, what they’re looking for and how they see the value in the STARS program,” says Xavier Williams, a sophomore from Orlando majoring in aeronautical and astronautical engineering, who says interactions with industry partners like L3Harris helped him recognize the importance of engineering flexibility.

“Their investment in this program really opened my eyes to how semiconductors are so important and how we don’t just need semiconductor engineers, but lots of different types of engineers who understand the importance of this industry,” Moreno says.

[The industry partners’] investment in this program really opened my eyes to how semiconductors are so important.

Emily Moreno Sophomore in aeronautical and astronautical engineering

Rebuilding the U.S. semiconductor presence

For the U.S. to succeed in its ambitious efforts to reshore semiconductor production and fill these new fabrication plants with skilled workers, it must convince students like Skyler Collins to give the field a try.

A 25-year-old former Marine with a wife and infant daughter, Collins’ motivations are different than many of his STARS colleagues. The junior in mechanical engineering technology from Frankfort, Indiana, applied to the program following encouragement from a former Ivy Tech professor who was aware of his interest in technology and desire to find a secure occupation that will help him support his young family.

“I’m exploring opportunities and seeing if I like it. It seems interesting, and the fabrication facility SkyWater is building is supposed to open around my graduation date, which lines up perfectly,” Collins says.

For those STARS students who eventually find employment in one of the nation’s new semiconductor facilities, Walter says it’s important to note that they will not simply duplicate work already being done in massive overseas facilities like the $228 billion cluster that Samsung plans to build in South Korea.

A key element of the CHIPS Act, Walter says, is not just to restore chip manufacturing on this continent, but also to spur innovation that will help the U.S. reclaim a critical leadership position within the industry. American workers must be prepared to break new ground.

“The way we used to do things isn’t going to continue to work. They need to change the industry in order to progress,” Walter says. “We’d be crazy to try to compete with these big plants in other parts of the world, but we can take their product and build upon it and make something better. I think that’s the direction we should go, and I think that’s the direction we are going.”

Purdue alone cannot resolve its home nation’s semiconductor workforce concerns, but initiatives like the new degree offerings and STARS program can function as a template for other universities to emulate. As the CHIPS Act funding rolls out, these efforts should benefit the U.S., the chip makers, the universities and the young engineers who enjoy new career opportunities at a time where their country needs their talents.

“When you think about manufacturing semiconductors in the U.S. and how important this is, it’s amazing that I get to be part of this program,” Bingham says. “You see posters on the wall at Birck about all the incredible things that Purdue is doing and how senators are endorsing it, and it just makes you very, very proud to be a Purdue student.”